No drilling, no milling! This guarantees quick and easy assembly. Robotunits unique Fastening Technology plays a decisive role here. It offers strength comparable to welding technology, with an impressive tensile force of up to 4 tons – all achieved with just a single connection. In short: maximum strength at an attractive price. Robotunits Fastening Technology is also characterized by its low overall height and enables unlimited reusability.

No drilling, no milling! This guarantees quick and easy assembly. Robotunits unique Fastening Technology plays a decisive role here. It offers strength comparable to welding technology, with an impressive tensile force of up to 4 tons – all achieved with just a single connection. In short: maximum strength at an attractive price. Robotunits Fastening Technology is also characterized by its low overall height and enables unlimited reusability.

With Robotunits, you can connect aluminum extrusions without drilling or milling – using simple standard screws and space-saving, fully load-bearing fasteners on both sides. Thanks to the unique Robotunits Fastening Technology, a single component is sufficient for double-sided fastening. This allows you to position and install quickly, flexibly, and precisely.

Features

Fastening Technology 40mm Series Features

- Worldwide unique form-fitting and play-free centrally aligned Fastening Technology

- Connect without drilling and milling

- Two-sided connection with only one fastener

- Outstanding process reliability and 100 % repeatability

- Short design and assembly time easy, post-assembly repositioning

- Strength comparable to a welded connection

Applications

Fastening Technology 40mm Series Applications

- Robotunits Workbenches

- Cobot Station

- Pick-up station for AGVs

Products

Fastening Technology 40mm Series Products

Fastener 16x40

Fastener 16x40

Application: 90° fastener for extrusion PIL 1640.

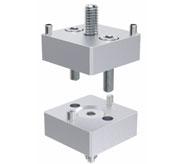

Fastener 40x40

Application: 90° fastener on 40mm series for extrusions PIL 4040 and PIL 4080 transverse.

Fastener 40x80

Fastener 40x80

Application: 90° fastener for extrusions 40×80 and 80×80

Surface Fastener 40x40

Surface Fastener 40x40

Application: Used for connection to non-Robotunits surfaces on 40mm series for extrusion PIL 4040.

End-to-End Fastener 40x40

End-to-End Fastener 40x40

Application: For end-to-end connections of the 40mm series for extrusion PIL 4040.

Angle Fastener 45°

Angle Fastener 45°

Application: for rigid 45° bracing, e.g., guardings, frames

Elbow Joint 40

Elbow Joint 40

Application: for variable angle connections, e.g., guardings, frames, swing arms

Q & A

Extrusion Technology 40mm Series Q & A

Downloads

Robotunits Extrusion and Fastening Technology Catalog

Robotunits Fastener Loads Datasheet

Robotunits Extrusion Tolerances Datasheet

Call us today at (855) 737-4716 to learn more, or fill out our online form and someone will get back to you.